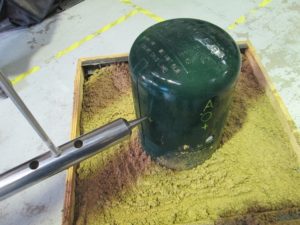

Austest performs accredited Ingress & Enclosure Protection Testing

Enclosure Protection testing involves assessing ability of the product or its enclosure to provide protection against:

- ingress of water (drip, spray, jet, immersion)

- ingress of dust

- solid foreign objects

- access to hazardous parts

- mechanical impact

Levels of protection against water, dust, solid foreign objects and access to hazardous parts are defined by IEC 60529 and its derivatives such as AS 60529. This standard is commonly referred to as “IP Code” and is referenced by many commercial, industrial and consumer product standards.

Protection against impact is standardised in similar manner by IEC62262 (also known as “IK code”) and IEC60068-2-75 specifications.

Additionally, defence equipment is usually tested to relevant sections of MIL-STD-810 or DEF STAN 00-35 standards, while RTCA DO-160 is prevalent for aerospace applications and ISO20653 for automotive use.

Austest Laboratories operates enclosure protection testing facilities at its NSW, VIC and SA sites featuring:

- Ingress protection testing up to IP69K rating

- 4 dust chambers, up to 25 m3

- Immersion testing up to 6000 m depth

- Testing to defence, aerospace and automotive specifications:

- MIL-STD-810G

- DEF STAN 00-35

- RTCA DO-160G

- ISO20653

- On-site testing

Impact testing, pendulum hammer - Spring, Pendulum and Drop hammer impact testing, up to IK10 rating

- Specialized impact tests (e.g. AS3439-5)

- High speed impact up to 500 J

- Post-test electrical evaluations

Here are the various numerals explained in basic terms covering Ingress Protection (please refer to the standard AS/NZS 60529 for specifics):

IP First Numeral – Protection from solid objects/dust, IP

| IP0X | No protection |

| IP1X | Protection against solid objects > 50 mm |

| IP2X | Protection against solid objects > 12 mm |

| IP3X | Protection against solid objects > 2.5 mm |

| IP4X | Protection against solid objects > 1 mm |

| IP5X | Protection against dust (limited ingress allowed, no harmful deposit). |

| IP6X | Fully protected from dust (dust tight). |

IP Second numeral – Protection from moisture/liquids

| IPX0 | No protection. |

| IPX1 | Protection from vertically dripping water |

| IPX2 | Protection from sprays/dripping of water up to 15ofrom vertical. |

| IPX3 | Protection from spraying water up to 60o from vertical. |

| IPX4 | Protection from spraying water (all directions) – limited ingress OK provided no hazard. |

| IPX5 | Protection from low pressure jets of water (all directions) – limited ingress OK provided no hazard. |

| IPX6 | Protection against powerful jets of water, limited ingress OK provided no hazard |

| IPX7 | Protection from temporary immersion |

| IPX8 | Protection from continuous immersion |

Austest is accredited for testing to the impact standard for IK ratings, IEC 62262. The IK ratings vary depending on intended use. Street lights have a minimum IK04, moderate resistance IK06, high – IK08 according to AS 1158.6 (Resistance to vandalism).

| IK code | IK00 | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK010 | |

| Impact energy, J | . | 0,14 | 0,2 | 0,35 | 0,5 | 0,7 | 1 | 2 | 5 | 10 | 20 | |

| *Not protected according to the standard | ||||||||||||

| NOTE 1 | When higher impact energy is required, the value of 50J is recommended. | |||||||||||

| NOTE 2 | A characteristic group numeral of two figures has been chosen to avoid confusion with some national standards which used a single numeral for a specific impact energy. | |||||||||||